Elasticity, strength, friction and porosity relations in Discrete Element Method (DEM) models of cohesive granular materials

Schöpfer, M.P.J., Abe, S. 1,2, Childs, C. & Walsh, J.J.

1 - Seismology & Computational Rock Physics Laboratory, School of Geological Sciences, University College Dublin.

2 - Present address: Geologie-Endogene Dynamik, RWTH Aachen University, Aachen, Germany.

Abstract - Laboratory tests of sedimentary rocks (e.g. sandstones, limestones) indicate that rock strength, angle of internal friction and Young’s modulus decrease with increasing porosity. If core samples for rock mechanics testing are not available, rock physical properties are estimated using empirical relations, i.e. Young’s modulus is estimated from a sonic log and other properties (unconfined compressive strength, friction angle) using other empirical relations. Since some of these empirical relations are poorly constrained, our study attempts to provide an improved mechanical basis for their determination. The Discrete Element Method (DEM), in which rock is represented by bonded spherical particles, is used to investigate the shape of failure envelopes and relations between friction angle and porosity. A series of confined triaxial extension and compression tests were performed on samples generated with different particle packing methods in order to test whether the mechanical properties of the model material are predominantly controlled by particle size distribution or porosity. The impact of pre-existing cracks, which were modelled as non-bonded contacts, on mechanical properties was also investigated.

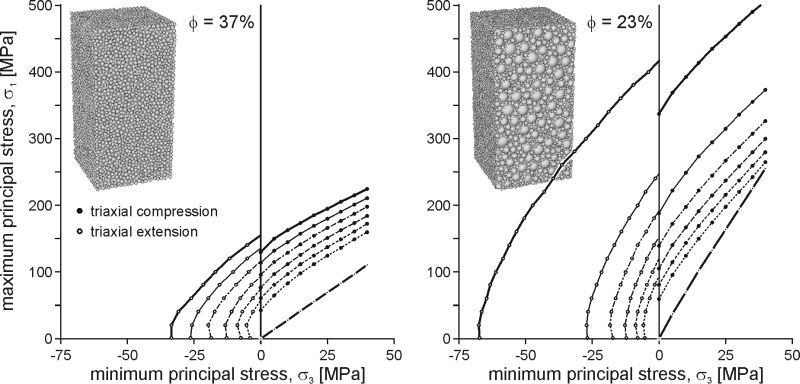

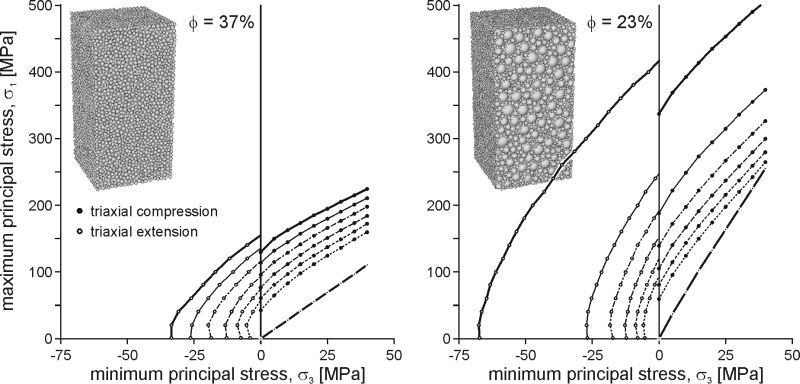

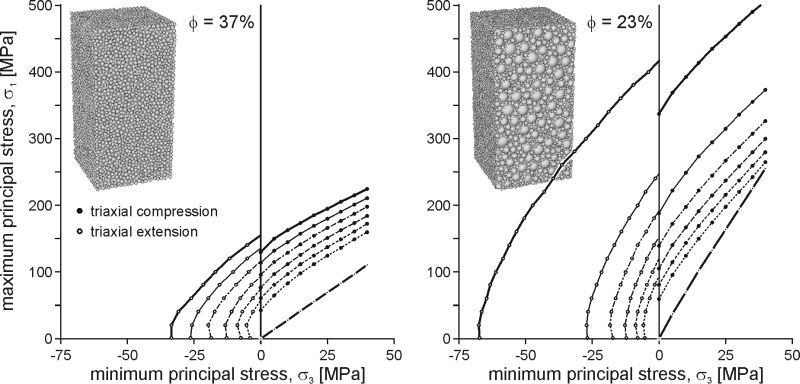

Figure 1: Failure envelopes in principal stress graphs obtained for two models with different porosities but identical particle and bond properties. The strongest materials are fully bonded, whereas the weakest materials are non-bonded. The envelopes in-between were obtained from partially bonded models.

Our 3D DEM models for both uniform (Fig. 1a) and power-law (Fig. 1b) particle size distributions and varying cement content demonstrate that the friction angle decreases (almost) linearly with increasing porosity and is independent of particle size distribution. Young’s modulus and strength decrease with increasing porosity, whereas Poisson’s ratio is (almost) porosity independent. The unconfined compressive strength to tensile strength (UCS/T) ratio is controlled by model porosity, but also by the proportion of bonded contacts, i.e. UCS/T increases with increasing crack density. Young’s modulus and strength decrease and Poisson’s ratio increases with increasing crack density. All our 3D DEM model property relations (strength, friction angle, stiffness) are consistent with continuum mechanics predictions and empirical rock property relations. The modelling results not only provide a rationale for empirical relationships between the mechanical properties of rock and other parameters, but also underpin improved methods for the calibration of DEM model materials.

Abstract of talk given to:

Tectonic Studies Group Annual Meeting, La Roche-en-Ardenne, Belgium, January 2008.

|